Electric Torque Controller / Wattage Based

- Latest Micro-Controller Chip Installed for controlling the functions of Unit & single circuit board for easy maintenance.

- The LED on Torque Controller helps to indicate the connection of drive automatically.

- To produce indentical results it is accurately calibrated digital torgue setting with resolution of 1 watt which makes torque setting accurate.

- For long life of the system soft start is provided for all drive reducing starting curren in the drive.

- Four different torque setting suitable for four different drives.

- To avoid absued or overused appropriate wattage range is automatically selected for connected drive.

- On pressing button on LED actual drive wattage(torque),Set Wattage(torque), drive current & voltage line is displayed on LED.

- The system is adjustable for Reverse time from(1sec – 100 sec), Trip time (0.1 – 10 sec), Pause time(interval time between cycles), Adjustable from(01 sec – 100 sec) In emergency case push buttom manual reverse push button can be used.

- Two mode is been used Foot Switch & Hand (trigger) also speed of the drive is adjusted with help reverse rotation.

- Two mode can be used for Expansion either in Single Mode or Auto repeat Mode.

- The Drives are well protected over current by short circuits with help of MCB.

- At the time of trouble shooting Plug in type PCB’s are used which reduce down time.

- Forward, Reverse & Trip indication are provided on LED Indicators.

- The system is designed with High Quality SCT Technology, which have better voltage, current & dv/dt ratings that triacs. This benefit to the power circuit & reliability it becomes failsafe.

- Only one Instrument can be used for replacements of spares inside the panel such as PCB’s, Transformers, CT, and Relays DPM etc.

- The system can be compatible with PC / Printer also.

| Model No. |

VoltageSingle Phase 50/60 Hz |

Weight (Kg) |

| TCW-09-110 |

110V |

11.0 |

| TCW-09-230 |

230V |

11.0 |

Note : Voltage Stabilizers for use with TCW torque controllers. All TCW torque controllers are supplied with operation manuals.

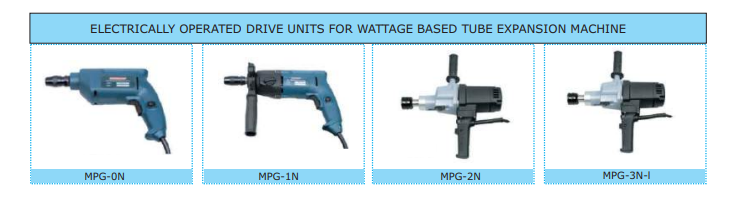

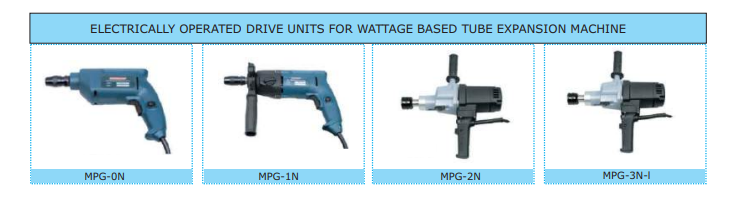

ELECTRICALLY OPERATED DRIVE UNITS FOR CURRENT BASED TUBE EXPANSION MACHINE

FEATURES:

- It consists of heavy duty German Made motors.

- Continuous cycle operation vs. Intermittent cycle operation of drives from other manufactures.

- High torque to weight ratio.

| Drive Model |

No Load Speed

R.P.M. |

Expansion Range |

Full Load Current AMPS |

Drive Weight

Kgs. |

| 230V |

110V |

S.Steel Tube

O.D/M.M |

Copper Tube

O.D/M.M |

230V |

110V |

| MPG-0N

|

MPG-0L

|

2800

|

6 to 10

|

6 to 12

|

2.6

|

2.6

|

2.0

|

| MPG-1N-l

|

MPG-1L-l

|

1000

|

10 to 16

|

13 to 20

|

6.0

|

6.0

|

2.5

|

| MPG-1N-ll

|

MPG-1L-ll

|

1900

|

08 to 13

|

11 to 16

|

| MPG-2N-l

|

MPG-2L-l

|

480

|

16 to 45

|

16 to 50

|

12.0

|

12.0

|

7.5

|

| MPG-2N-ll

|

MPG-2L-l

|

1080

|

16 to 32

|

16 to 38

|

| MPG-3N-l

|

MPG-3L-l

|

130

|

25 to 76

|

25 to 102

|

12.0

|

12.0

|

8.5

|

| MPG-3N-ll

|

MPG-3L-ll

|

430

|

25 to 50

|

25 to 76

|